25~500グラムのナッツを自動で袋詰めするソリューション

機械紹介:

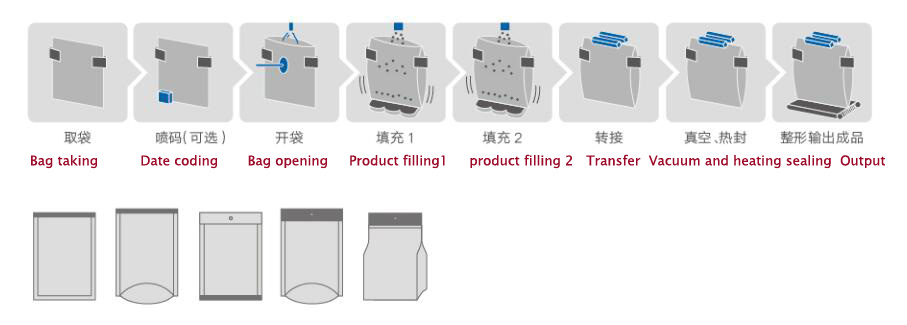

このユニットマシンには、2種類の異なる製品を計量できるZL20-1.6Lマルチヘッド計量機1台、ZL8-230ロータリー式袋取出し・開封・充填・シール機1台、DT5バケットエレベーター1台、安全プラットフォームと梯子1台が含まれています。本体はシーメンスPLCで制御され、タッチスクリーンで操作します。有名な電気付属品を採用しています。高度な自動化と簡単な操作性を実現。日用化学品、食品、化学薬品など、様々な業界で幅広く使用されています。

マシンの詳細:

1、ZL8-230型ロータリー包装機(ジッパー付きドイパッカー)

機能と特徴

1、操作が簡単で、シーメンスの高度なPLCを採用し、タッチスクリーンと電気制御システムと組み合わせて、マンマシンインターフェースはフレンドリーです。

2、周波数変換は速度を調整します:このマシンは周波数変換装置を使用し、生産の現実のニーズに応じて範囲内で調整できます

3、自動チェック:ポーチまたはポーチオープンエラーなし、充填なし、シールなし。バッグは再び使用でき、梱包材や原材料を無駄にしないでください。

4、安全装置:異常空気圧で機械停止、ヒーター断線警報。

5、バッグの幅は電気モーターで調整できます。コントロールボタンを押すと、クリップの幅を調整し、簡単に操作でき、時間を節約できます。

6、ガラス製の安全扉とのマッチングが可能です。同時に、ほこりを防ぐことができます。

7、プラスチックベアリングを使用し、オイルを塗る必要がなく、汚染が少ない。

8、オイル真空ポンプを使用せず、生産中の環境を汚染しないようにしてください。

9、梱包材の損失が少なく、この機械は予め成形された袋を使用しており、袋のパターンは完璧で、シール部分の品質が高く、製品の仕様が向上しています。

10、製品や包装袋の接触部分には、食品衛生要件に適合したステンレス鋼またはその他の材料を採用し、食品の衛生と安全を保証します。

11、固体、液体、濃厚な液体、粉末などを詰めるためにさまざまなフィーダーが変更されました

12、この包装袋は広範囲に適しており、多層化合物、単層PE、PPなどに適しています。

フィルムと紙で作られた成形済みのバッグです。

仕様

| モデル | ZL8-230 |

| 作業位置 | 8作業位置 |

| ポーチ材料 | ラミネートフィルム |

| ポーチパターン | ジッパーとピローバッグ付きのドイパッカー |

| ポーチサイズ | 幅:100~230mm 長さ:150~350mm |

| 速度 | 10~35袋/分(速度は製品の状態と充填量によって異なります) 重さ)) |

| 重量 | 1400KGS |

| 電圧 | 380V 3相50HZ / 60HZ |

ZL20-2.5Lマルチヘッド複合計量機

適用範囲:

単一材料の高速計量、複数材料の配合混合に適しています。最長材料は 60 mm、単一材料は 60 g 未満、インスタントオートミール、ミックスナッツなどです。

特徴:

高速モードは単一の材料に使用できます。

混合物の重量は最後の材料の操作によって補正できます。

高精度、高水準の特殊センサーを使用。

インテリジェントな障害アラームプロンプト、メンテナンスがより便利になります。

高速同期排出機能により、材料の詰まりを効果的に防止します。

高度に統合されたモジュール設計は CAN バス テクノロジーを採用しています。

Modbus業界標準通信プロトコルは、組み合わせスケールと包装機インターフェースの組み合わせを実現します。

同世代モデルのその他の機能と特徴。

粘性材料の場合、60°シャーシやテフロンコーティングなどの固着防止策を使用できます。

機械的特性および製品特性:

さまざまな混合配合材料には個別の上部ホッパーが使用されます。

独立した主振動機を採用し、異なる材料の供給厚さをそれぞれ制御します。

一体型シャーシとミドルシートにより機械の剛性と強度が向上し、計量精度が向上します。

シャーシとシュートは互換性のある設計を採用しています。単一材料を計量する場合は、ダブルポートのアンロードトレイに交換して、ダブルパッキング機に装備することができます。

統一された設計基準と金型製作工程により、各部品の互換性が強化されます。

安定したアルミシェル構造により、ホッパーの動作がより安定し、測定値の精度が向上します。一体型シャーシとミドルシートにより機械の強度が向上し、ホッパーの安定時間が短縮されます。

仕様:

| モデル | ZLJ20-2.5L |

| コード | A20-2-2 |

| 目標体重 | 10~1000グラム |

| 正確さ | バツ(0.5) |

| 最高速度 | 65B/M(混合品)/100B/M単品 |

| ボリューム | 2.5L |

| タッチスクリーン | 10.4' |

| オプション | ディンプルプレート/タイミングホッパー/プリンター/リジェクト装置 |

| ドライブモード | ステップモーター |

| 力 | 220V/2000W/50/60Hz 16A |

| 梱包寸法 | 1920*1650*1620 |

| 機械重量 | 850kg |